To develop our product-specific EPD's, we use for example a generator from LCA Norway, verified by EPD Norway. With this tool, we can calculate a verified carbon footprint for all cable materials and processes, thereby summarizing an overall environmental profile of a finished cable. The documents themselves are published via EPD Norway.

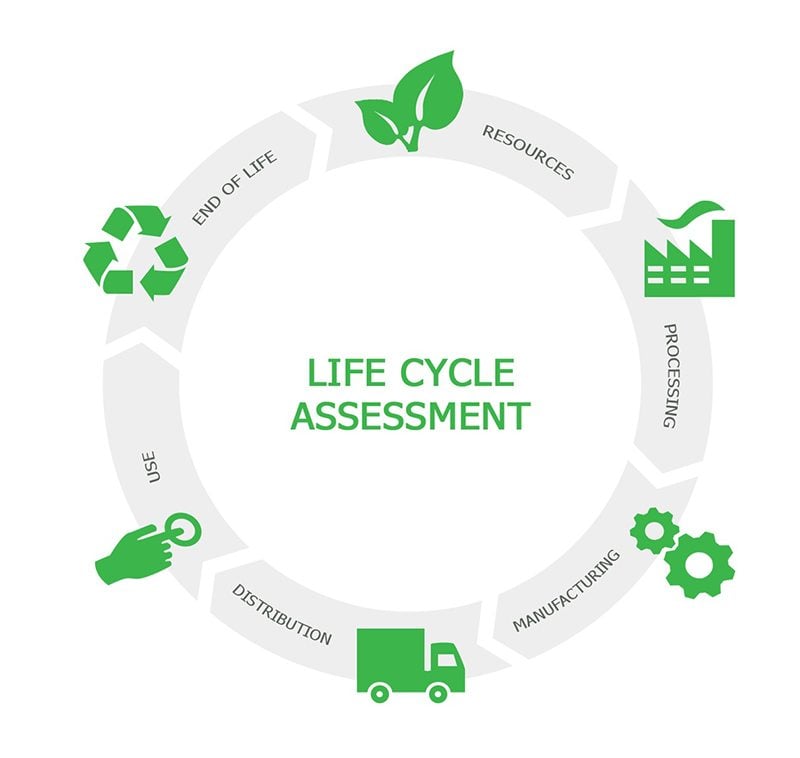

A life cycle assessment (LCA) is a standardized method of providing information about energy and resource consumption, waste generation and environmental impact, as well as the use and disposal of a specific cable. It maps the environmental properties of a cable over its entire lifetime - which in principle corresponds to a full EPD from cradle to grave.

- The product phase (A1-A3) deals with the sourcing of raw materials, the transport to the production site and the manufacturing phase (cradle to gate).

- The construction process phase (A4-A5) deals with transport from factory to construction site plus the construction process on site.

- The use phase (B1-B7) deals with the environmental impact during the period of use, including maintenance, repairs or replacements.

- End of life (C1-C4) deals with the effects of dismantling or demolition, transport to waste treatment and disposal processes.

- Reuse, recycling or recycling potential (D).

The EPDs are specified according to standard ISO-14025 type III and EN 15804:2012 +A2:2019 and are prepared on the basis of a life cycle analysis (LCA) according to ISO-14040-14044, while the content complies with requirements and guidelines for ISO-1402. Further, they are subject to the product category cPCR (Product Category Rules) for cables and wires NPCR 027.2022 Part B.