OVERVIEW

Low-carbon solutions

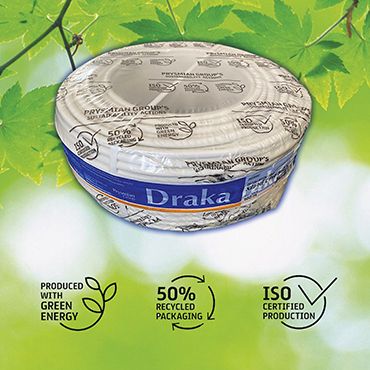

Sustainability is central to Prysmian Group's business strategy and integrated into all parts of our value chain.

Our factories are therefore, focusing on both reducing their consumption of packaging materials as well as maximizing their consumption of circular packaging materials.