OVERVIEW

Market maturity

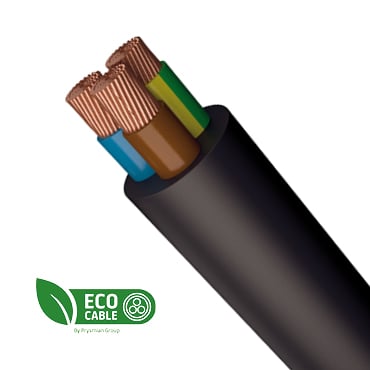

For electrical cables used in buildings or the utility sector, the metal conductors and screening traditionally have accounted for the predominant part of a cable's carbon-footprint.

However, thanks to an increased marked availability and affordability of clean energy combined with more recycling of metal waste - cable manufacturers are finding it economically feasible to transition towards using recycled or low-emissions metals for cable conductors and screening.

The market for sustainable alternatives has reached a level of maturity, coinciding with an increased customer demand for environmentally friendly cable solutions.